Our Production Machinery at Jindal Polycompounds

At Jindal Polycompounds, we are committed to delivering high-performance polyamide products that meet the most exacting industry standards. To achieve this, we have invested in state-of-the-art production machinery that allows us to manufacture our products with precision, consistency, and efficiency. Our advanced machinery is the backbone of our production process, enabling us to create superior materials like Nylon 6 and Nylon 66 that are tailored to the specific needs of our clients.

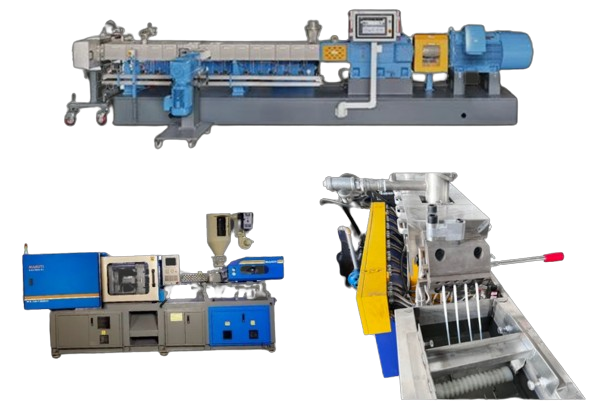

High Torque Twin Screw Extruder

The heart of our production line is the High Torque Twin Screw Extruder, a German-engineered machine known for its efficiency and precision in the compounding process. This machine is designed to handle a variety of tasks, including compounding, filling, and coloration of polyamide materials. With its high capacity and consistent output, the Twin Screw Extruder ensures that our Nylon 6 and Nylon 66 compounds are of the highest quality, meeting the exact specifications required by our clients.

The Twin Screw Extruder’s advanced technology allows for precise control over the compounding process, ensuring uniform distribution of additives and fillers throughout the polymer matrix. This results in materials with consistent mechanical properties, superior performance, and enhanced durability. Whether it’s for automotive parts, industrial components, or consumer goods, the compounds produced by our Twin Screw Extruder are designed to excel in demanding applications.

Customized Solutions with Tailor-Made Products

At Jindal Polycompounds, we understand that every client has unique needs. That’s why our production machinery is equipped to offer customized solutions, providing tailor-made products that meet specific requirements. Whether it’s producing polyamides in specific colors or creating compounds with specialized properties, our production machinery can handle it all.

We specialize in engineering and commodity thermoplastics, including both virgin and high-performance recycled materials. Our machinery allows us to create products with precise characteristics, whether it’s enhancing impact resistance with glass-filled grades or maintaining flexibility with unfilled grades. This versatility in production ensures that we can cater to a wide range of industries, including automotive, electrical, textiles, and more.

High-Capacity Production for Consistent Quality

Our production machinery is designed for high-capacity output, ensuring that we can meet the demands of large-scale orders without compromising on quality. The integration of advanced automation and control systems in our machinery allows for continuous monitoring and adjustment of the production process, ensuring that every batch of material meets our stringent quality standards.

This high-capacity production capability is crucial for industries that require a steady supply of high-quality materials, such as automotive manufacturing or large-scale industrial applications. By maintaining consistent production quality, we ensure that our clients receive materials that are reliable, durable, and perfectly suited to their needs.

Commitment to Innovation and Sustainability

At Jindal Polycompounds, our production machinery not only reflects our commitment to quality but also our dedication to innovation and sustainability. We continuously invest in the latest technology to improve our production processes, reduce waste, and minimize our environmental footprint.

Our machinery is designed to be energy-efficient, reducing the overall consumption of resources during the manufacturing process. Additionally, our focus on recycling and reusing materials within our production line ensures that we are contributing to a more sustainable future.